Introduce

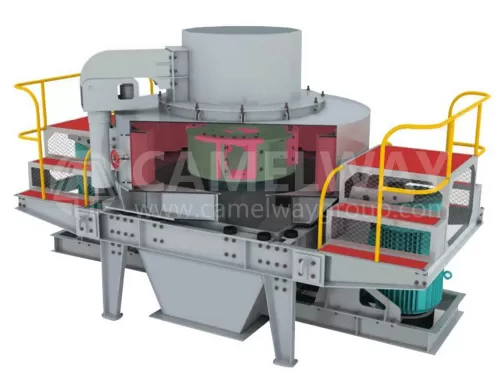

Sand making machine is the equipment which makes sand artificially. It can be an impact crusher or cone crusher according to the materiel condition and production requirement.

Sand making machinery is also a general term for the mechanical equipment that used for producing artificial sand. Sand maker can crush and screen natural stone materials and gain sand different granularity that can be used in daily life, so that it can also be called sand crusher.

The sand maker or VSI sand maker is suitable for the crushing and shaping of soft, medium hardness and extremely hard materials, such as various ores, cement, refractory materials, aluminum soil clinker, emery, glass raw materials, building stone and gold slag. Sand making machine or sand making machine has high efficiency in the crushing of extremely hard and corrosion-resistance materials like silicon carbide and emery.Sand making machine is widely applicable to grind hard, brittle materiel like all kinds of rocks, refractory materiel, cement clinker, quartz, iron ore, concrete aggregate, etc.It is especially suitable for making building sand and paving sand.

Because of its low wearable feature, sand making machine is also used in high abrasiveness and secondary crushing industry. Besides, because there is no pollution for machine, sand making machine is well suitable for producing glass quartz sand and other high-purity material industries. Its production capacity scope is 10-500t/h, so the sand making machine almost can satisfy all production requirements.

The Working Principle of Sand Maker

When sand maker works are driven by a motor. Rotor rotates in extreme high-speed. Materials enter into the first crushing cavity and strike against with the hammer of the rotor to be crushed, and then enter into the secondary crushing cavity to be crushed again. In the whole crushing process, it is not only crushing between material and hammer, but also stone strikes stone between each hammer and crushing cavity. At last, the final materials are discharged from the discharged mouth of the sand maker or sand making machine.

The Application of Sand Maker

1. The manufacturing of artificial sand. There are numerous materials come in handy, such as river gravel, rocks (limestone, granite, basalt, diabase, etc.), ore tailings, stone chips and so on.

2. The production of construction aggregates, asphalt concrete, road pavement materials, bedding material, concrete aggregate and cement aggregate.

3. Production of manufactured sand and stone shaping in the engineering projects like water conservancy and hydropower, high-grade highways, expressways, high-speed rail, passenger dedicated lines, bridges, runways, municipal engineering and high-rise buildings.

4. Fine crushing of the mining sector and material crushing of building materials, metallurgy, chemical industry, mining, refractory materials, cement and so on.

5. Production of high-purity materials like glass, quartz sand and others.

The Performance Characteristics of Sand Maker

1. Simple structure and low cost;

2. High efficiency and energy saving, high crushing efficiency;

3.CamelWay sand making machinery has functions for fine crushing and coarse grinding;

4. High passing rate of non-crushing materials and little influence of the material moisture. The moisture content of sand made by sand making machine or VSI sand maker can be up to 8%;

5. Crushing of medium hard and hard materials (such as corundum, sintered bauxite, etc);

6. Cubic shape of the finished product and little iron pollution

7. Easy operation and maintenance

8. Low working noise

9. Light weight and diversified installation.

Note

- The production capacity is measured in the laboratory under standard conditions, and is generally smaller in actual construction.

- Power refers to the average power, for reference only. Please be sure to contact us for advice before planning power supply.

- Container Qty refers to the number of containers required under standard configuration.

- Price refers EX reference Price, please contact us for the latest price and possible discounts.

- All product parameters provided are for reference only, and we reserve the right to change without notice.

GET QUOTE

GET QUOTE  WHATSAPP

WHATSAPP

3 Reviews