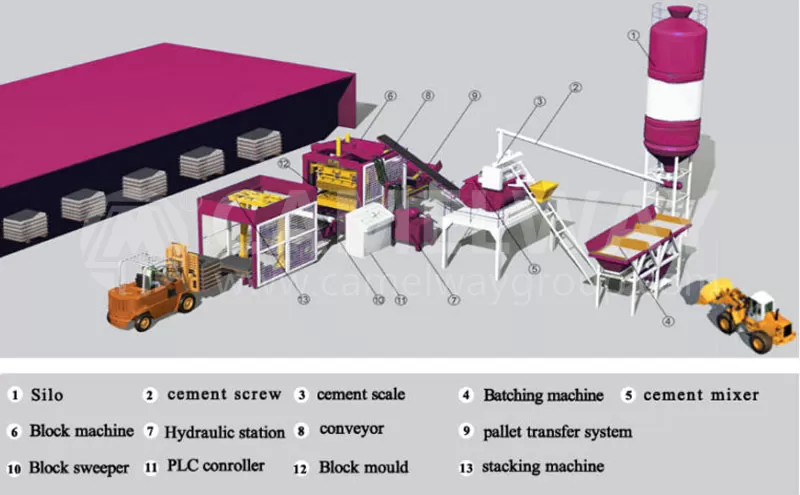

Stationary concrete batching plant 60m3/h is a factory for the manufacture of concrete block by using the latest technology in Doha, Qatar. In production, only sand is used as an inert aggregate, and when producing concrete block, the most important requirement for concrete is to carefully control of the sand fraction: It should not exceed 3 mm. To eliminate the negative impact on the extruder and on the final concrete product of particles with a large size, the scope of delivery included a system for feeding inert to the hopper with vibrating sieve. The 60m³/h concrete batching plant is equipped with a Twin Shaft Concrete Mixer with a selection device concrete samples and with three discharges: Two are used to feed machines for the manufacture of concrete block and other products, and the third is used for washing the Twin Shaft Concrete Mixer. In order to ensure prompt, non-stop supply of a certain amount of concrete to the machines, a hopper with a conveyor is installed under the Twin Shaft Concrete Mixer, the operation of which is controlled by a frequency converter.

As additional control and comfort elements, the concrete batching plant is equipped with a mixture moisture sensor in the Twin Shaft Concrete Mixer and a camera for monitoring the level of inert in the bins. The set of equipment was also successfully putting into operation and has been producing innovative high-quality products for more than a year.

Due to the fact that camelway singles out structural concrete projects in a separate direction, the automated system for such concrete batching plants is also developed individually for each project. Taking into account its features, which ensures accurate production and convenient operation of even the most complex projects. The main goal of CAMELWAY is to strengthen its position as a leader in the sector of customized concrete batching plants.

3 Comments